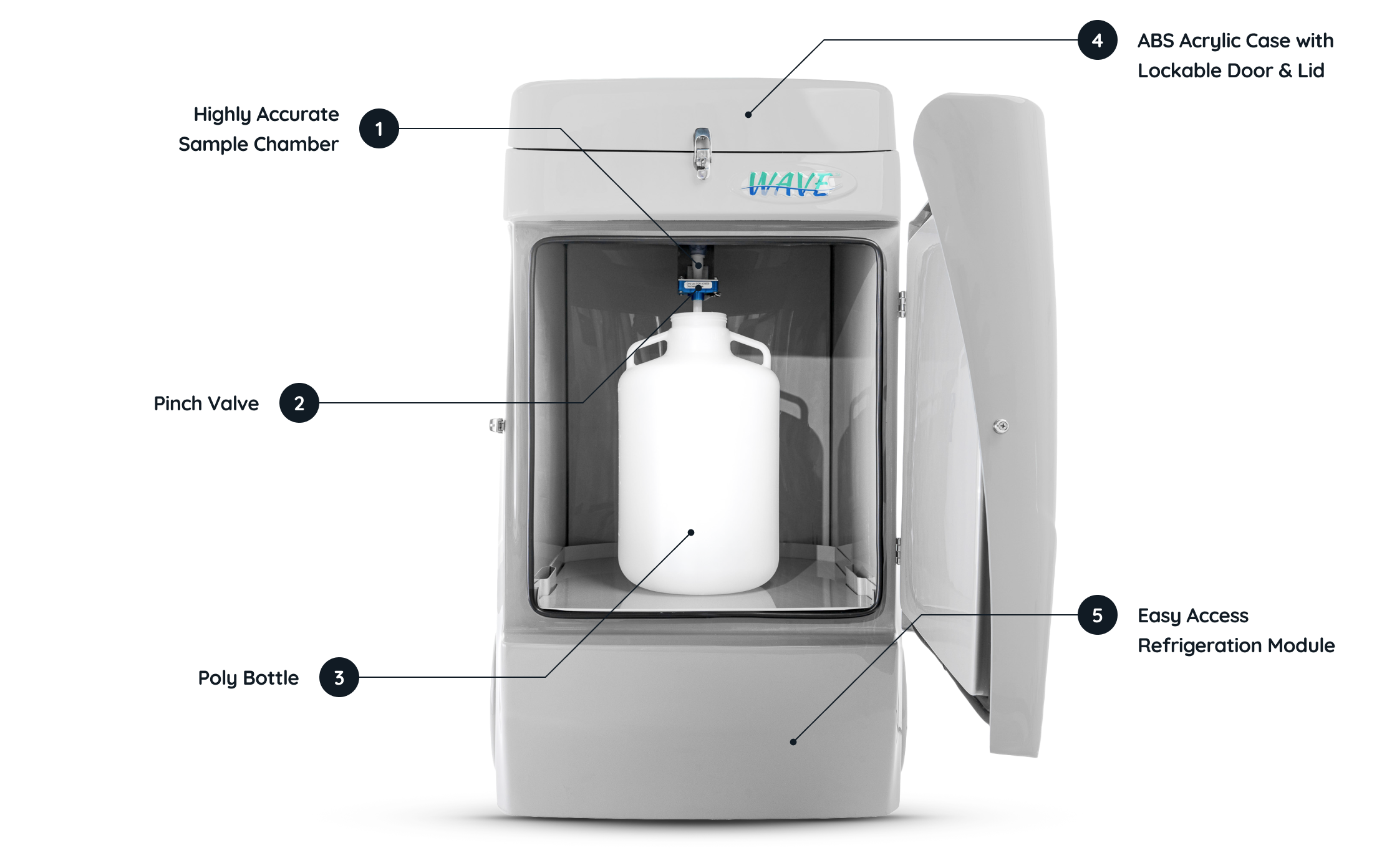

The WAVE™ uses a proprietary, patented design that makes it the best wastewater sampler on the market.

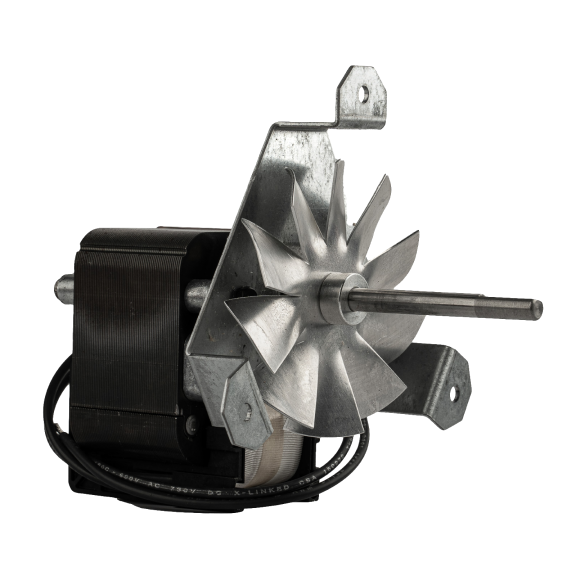

Built with a rotating arm and a programmable sample size - The WAVE™ sustains the integrity and accuracy of the sample due to the stronger purge and velocity, resulting in lower maintenance and precise volume every time.

Our product is built with trust and reliability in mind. We manufacture it in Pensacola, Florida so you can be confident that it meets the highest standards of quality and durability.

Simply fill out the contact form here and you will be contacted by our team of experts. We make the purchase process easy and seamless.

Yes. The proprietary technology in The WAVE™ is patented and developed by Emerald Coast Manufacturing. US PATENT#: 11,598,696 and #11,768,132

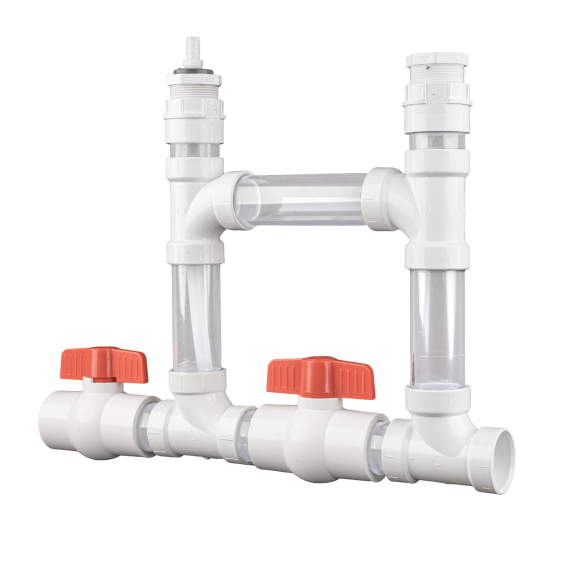

The WAVE™ Vacuum sampler uses a vacuum/pressure pump to provide the vacuum and pressure that moves the liquid. A chamber is used to hold and measure the liquid sample before depositing it into a container. The pressure pump forces air into the chamber, purging it and the intake hose of liquid, then draws liquid into the chamber until sample is complete. Then, the excess sample is purged out of the intake hose. Then the sample is deposited into the container.

Vacuum samplers do not have tubing wear. When the tubing is worn on the peristaltic sampler by 10%, it affects the sample size and velocities by 10%. Therefore, the sample sizes must be calibrated often, but the line velocity loss will remain. The line velocities could fall below the EPA recommendations. That loss of sample size and velocity is not seen in vacuum samplers.