Innovated by product developers and wastewater engineers with over 30+ years of experience in the wastewater industry.

Our proprietary technology uses a moveable arm and specialized sample chamber to produce accurate sample sizes every time.

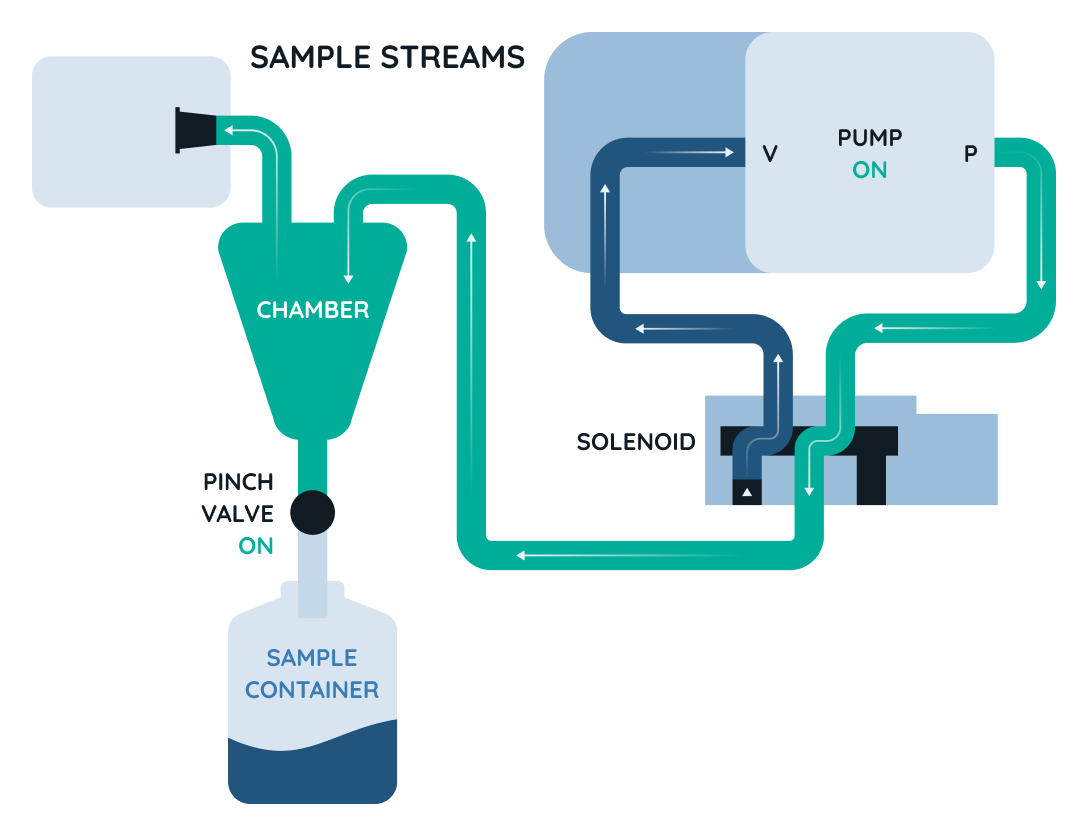

Pressure is applied to the chamber and intake line to make sure the line is clear from any residual liquid that may have entered into the intake line or strainer after the last sample.

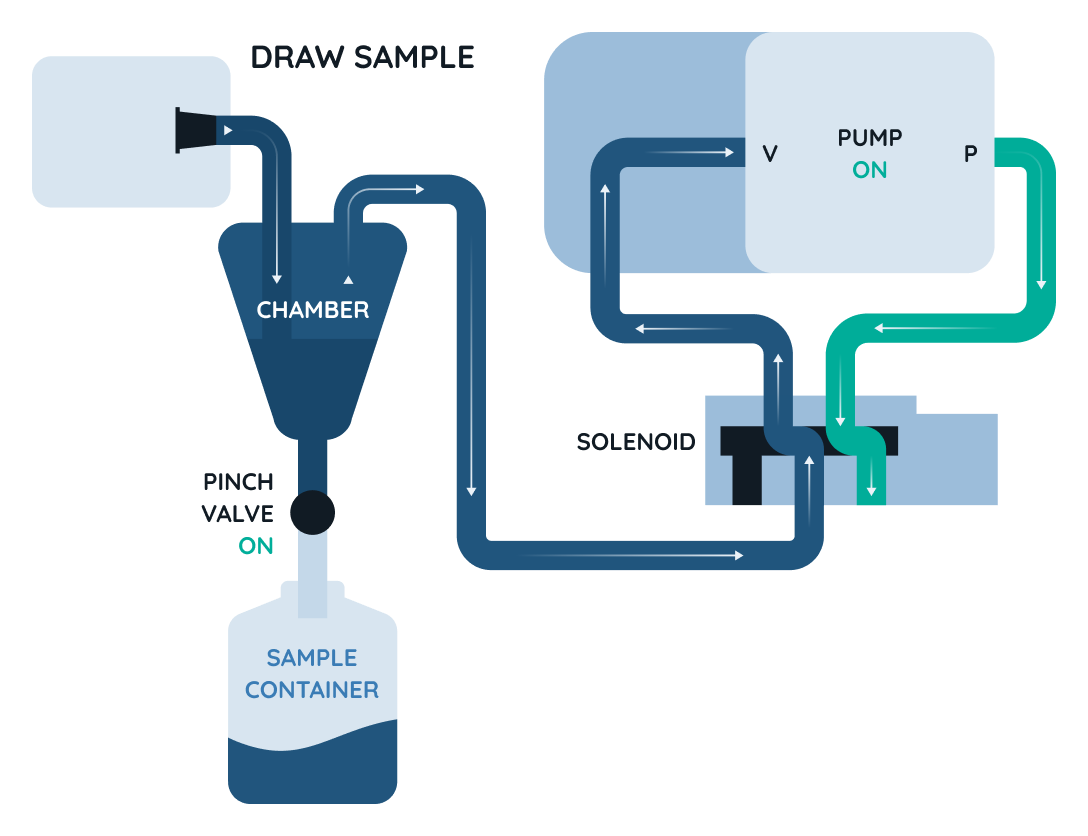

When the solenoid valve energizes, a vacuum is placed on the chamber and intake line to pull in liquid. When the liquid fills the chamber and triggers the non-contact liquid sensing device - it will know the chamber has received the proper amount of liquid to get an accurate sample size.

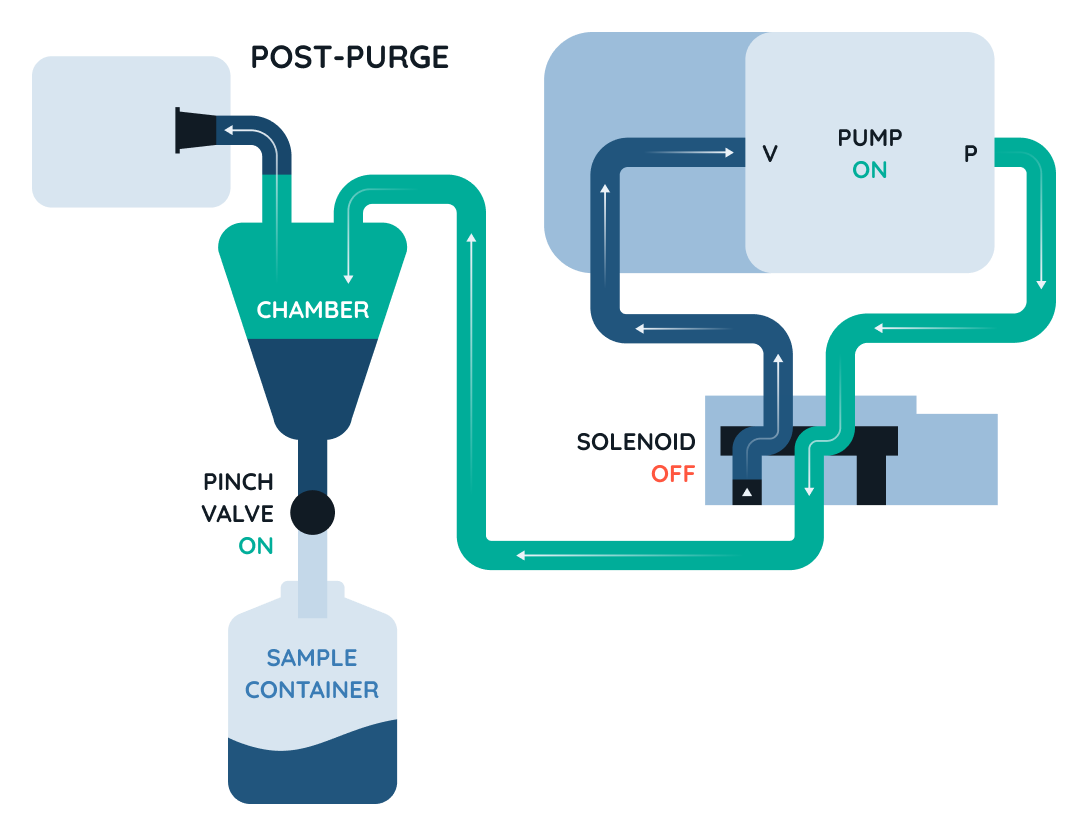

When water reaches the proper level in the sample chamber, a solenoid valve will de-energize, allowing the pressure to force the additional liquid out of the chamber and purge the intake line and strainer.

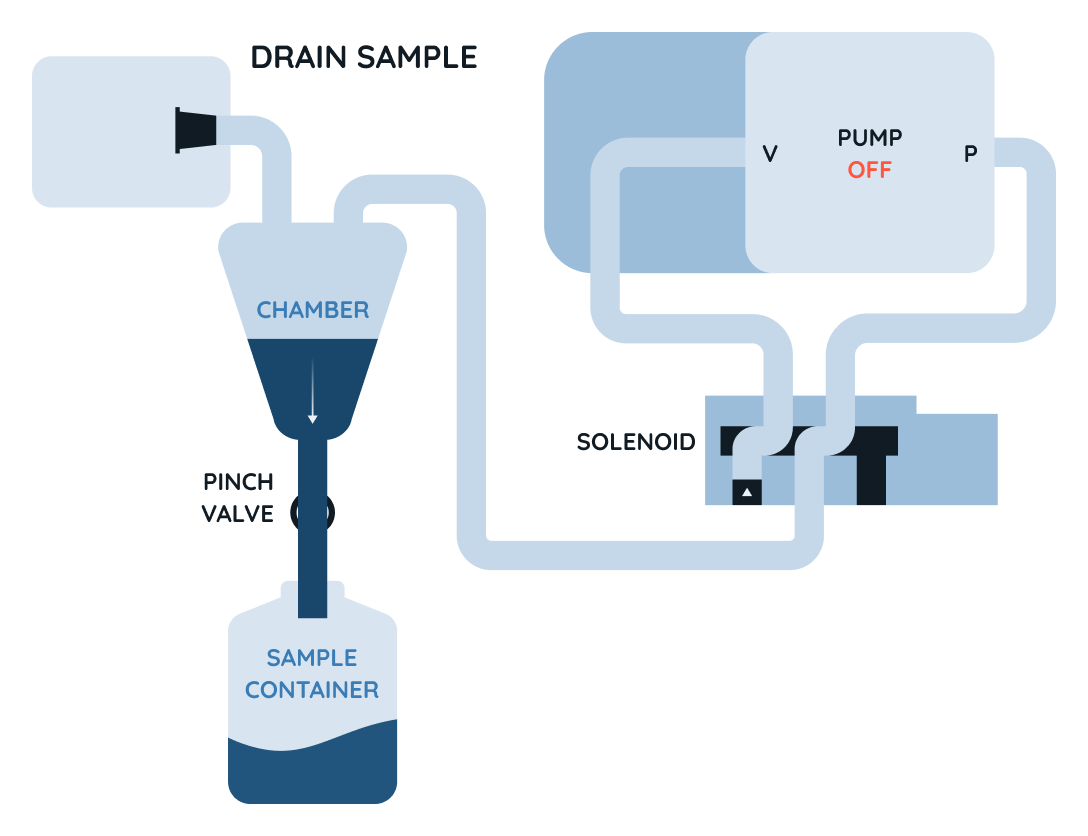

Once the intake line is purged, it will open the Pinch Valve and drains the liquid down to where the sample is being collected.

True to it’s name, this machine is making waves in the wastewater industry.

Utilizing state-of-the-art vacuum technology, The WAVE™ is built to last and designed to deliver unbeatable sampling accuracy in the wastewater industry. Its capabilities are fully configurable, giving you unparalleled precision that can stand up to any weather or environment.